Electric welding machine

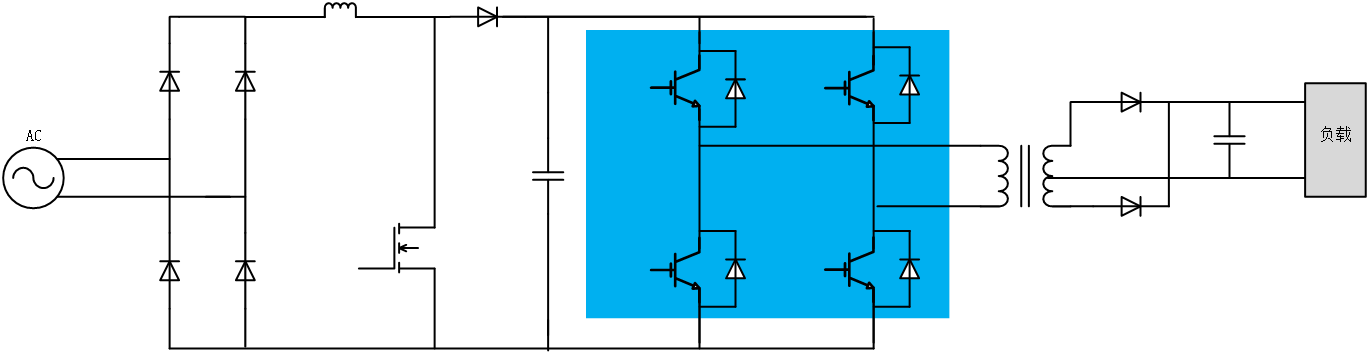

The working process of inverter welding and cutting equipment is to rectify and filter three-phase or single-phase 50Hz AC power frequency to obtain a relatively smooth DC power. The inverter circuit composed of IGBT or field-effect transistor converts this DC power into AC power of 15-100kHz. After being reduced by the intermediate frequency main transformer, it is rectified and filtered again to obtain a stable DC output welding current (or the required frequency AC power is output by inverter again). The control circuit of the inverter welding and cutting equipment consists of a given circuit and a driving circuit. By processing the feedback of voltage and current signals, the whole machine is controlled in a loop. The control technology with pulse width modulation PWM as the core is adopted to achieve fast pulse width modulation constant current characteristics and excellent welding and cutting process effects.

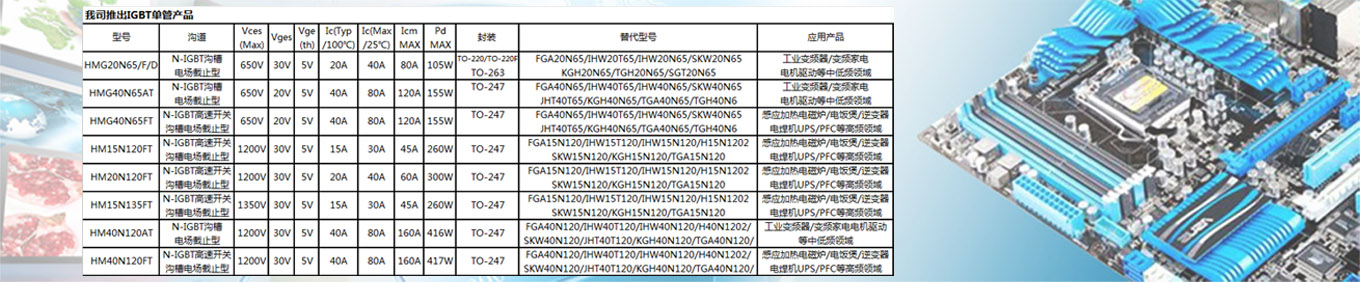

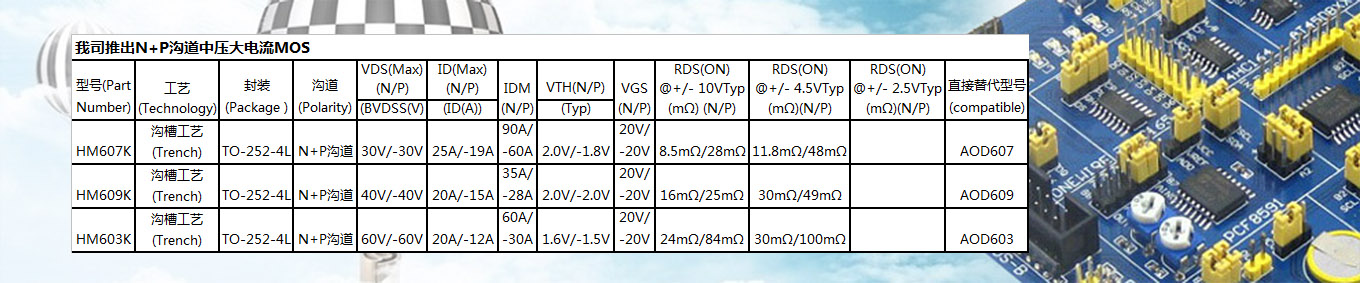

Developing welding machine specific IGBT using Trench FS technology for welding machines, which has lower shutdown losses, lower system temperature rise, stronger impact resistance, and strong cost-effectiveness.